WorkflowSEAT > HOME > Workflow

(1) data collection

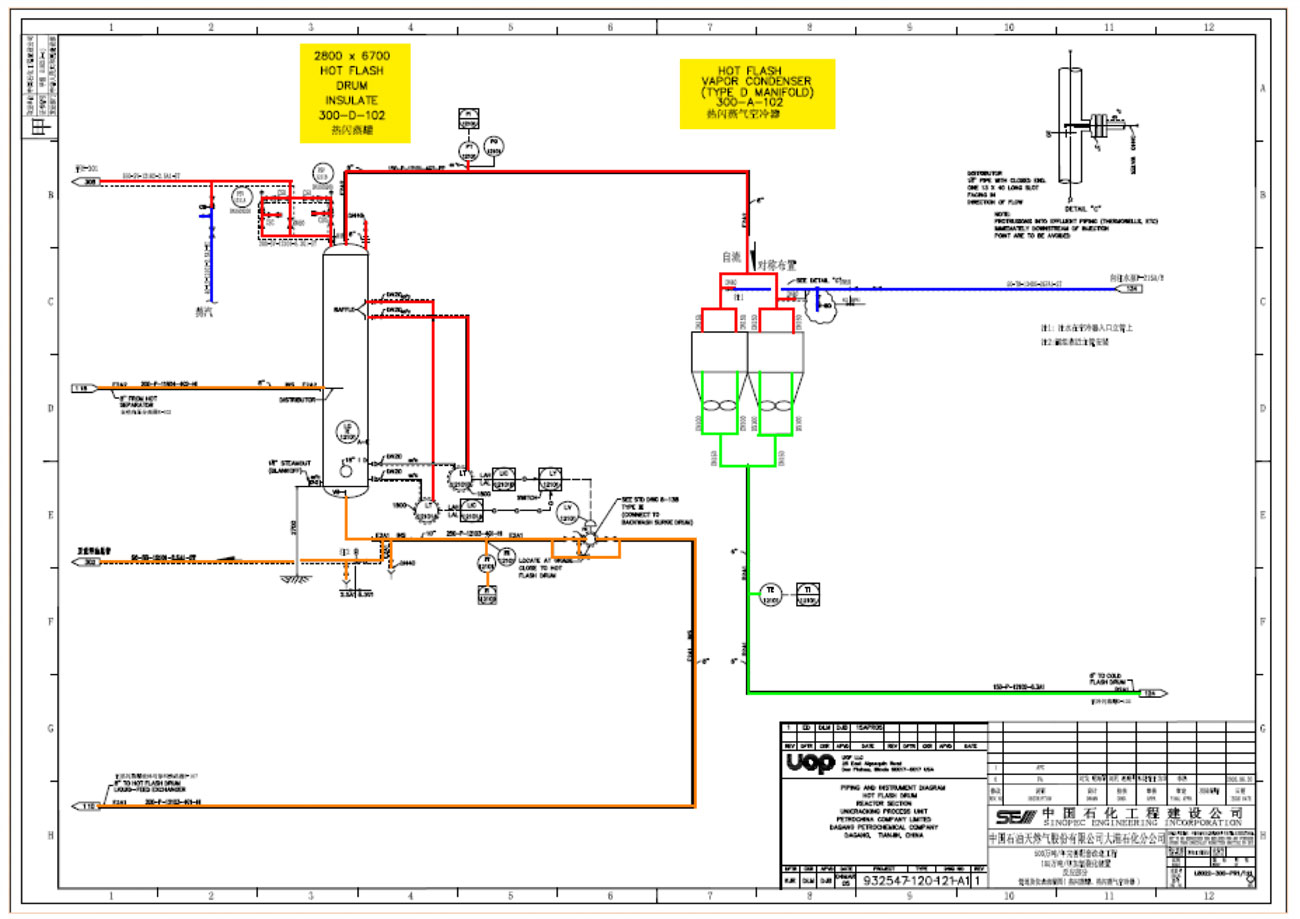

Need to collect equipment layout, PFD and P&ID drawings, equipment ledger, operating procedures, etc., to help the drawing auditor understand the equipment components, layout and process flow on site.

(2) drawing review

We will have professional technical engineers to determine the type and status of materials in the pipeline according to the logistics name, phase state, temperature pressure, mass flow rate, actual volume flow rate, actual density, molecular weight, acid value and characteristic factor on the collected drawings.

Pipeline highlighted on P&ID drawing will be checked on site at this stage. If P&ID drawing is inconsistent with the site situation, the drawings and marking will be modified as necessary. And according to the color of the highlighted pipeline, select the same color Flag (color ribbon) to hang on the corresponding pipeline. The main purpose of this process is to reflect the pipeline that needs to be tested on the drawing in the field pipeline, so as to facilitate the field implementation of the project.

(4) on-site listing

Based on the Flag status of each pipeline in the previous step, determine which components on the pipeline need to be detected and put a Tag Tag with obvious color and anti-weathering on the component to be detected. Each Tag Tag has an ID number. This process is mainly to test the component number, so that the next step to establish the ledger and statistical records.

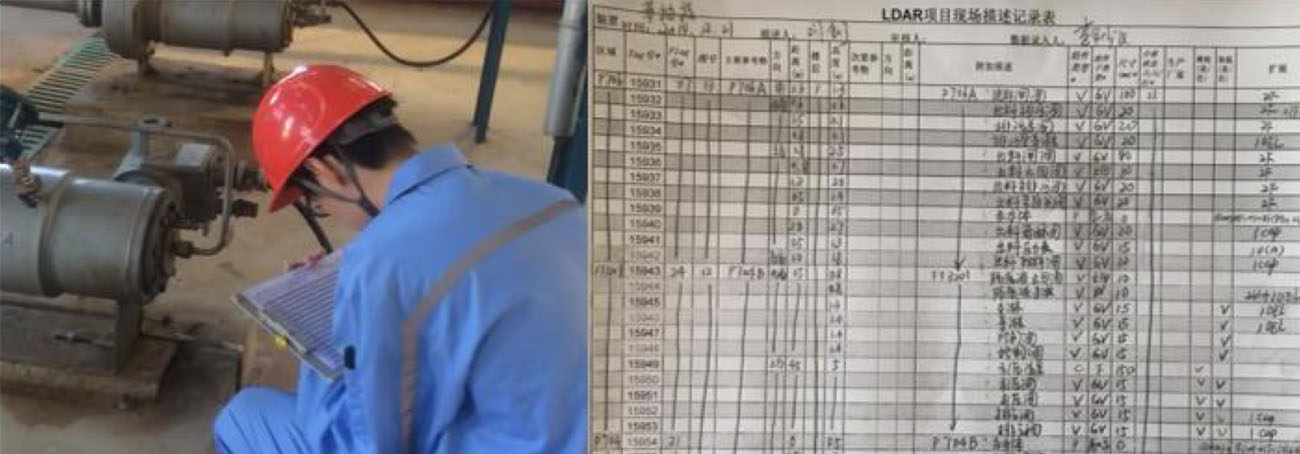

(5) field description

Record the component type, ID number, pipeline number, pipeline material status and other information of each component that needs to be tested, and summarize them uniformly.

Input the collected information of all test components into the LDAR management platform software, and establish a database ledger.

Selection of testing instruments for the TVA - 2020 - c portable volatile poisonous gas detector, for the convenience of testing, for each TVA supporting one hand operator, test before the start of work by hand operator connected LDAR information management platform to download to check components, the corresponding ID number for testing, all the testing data by hand on the mobile version of LDAR management platform, uploaded to the online edition of summary display. If leakage is detected on site, a leakage sign should be put up at the corresponding component location to prompt for maintenance staff. When the component maintenance is completed, the repaired component should be re-checked to see the maintenance effect.

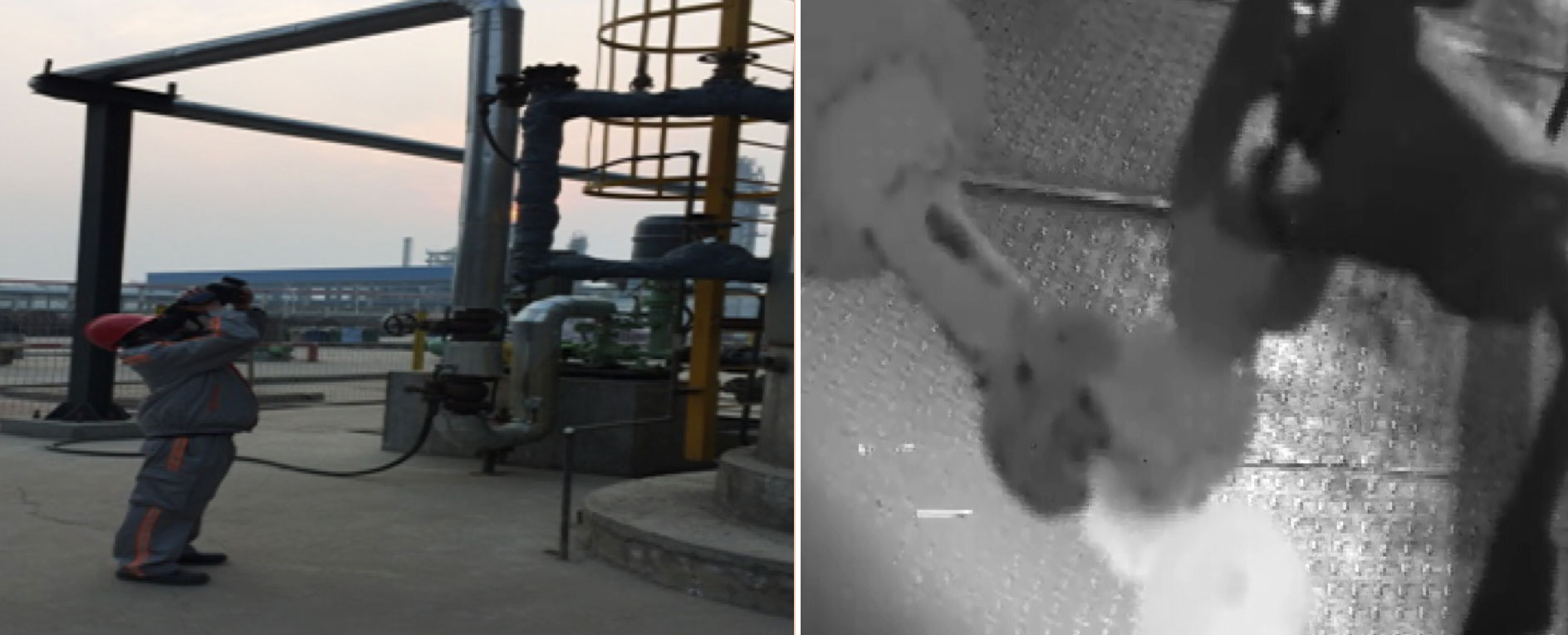

The equipment needed for infrared camera scanning detection is eye-c-gas infrared camera, which can see leakage qualitatively and intuitively. In the process of detection, some difficult components and dangerous components will be encountered. In this case, eye-c-gas needs to be used for supplementary detection, which records leakage in the form of pictures and video.

LDAR management platform can issue more than 20 reports, including test component information, leakage statistics, leakage rate statistics, and repair statistics.

(10) continuous cycle detection

In November 2015, the ministry of environmental protection issued the petrochemical industry leakage detection and repair work guide, which stated: "pumps, compressors, valves, open valves or open pipelines, gas/steam pressure relief equipment, sampling connection system shall be tested every three months; Flanges, other fittings and other sealing equipment are tested every 6 months. Therefore, the VOCs seal point after building the file shall be tested regularly to minimize the potential safety hazard caused by VOCs leakage in petrochemical enterprises.